Injin sukurin ƙwallon Nema 23 (57mm) mai haɗakar ƙwallo mai kusurwa 1.8° Wayoyin jagora na mataki 4 don kayan aikin bincike na likita

Injin sukurin ƙwallon Nema 23 (57mm) mai haɗakar ƙwallo mai kusurwa 1.8° Wayoyin jagora na mataki 4 don kayan aikin bincike na likita

Injin Nema 23 (57mm) mai haɗakar stepper, bipolar, mai jagora 4, sukurori na ƙwallo, ƙarancin hayaniya, tsawon rai, aiki mai girma, takardar shaidar CE da RoHS.

Babban ƙarfin kaya, ƙaramin girgiza, ƙaramin amo, saurin sauri, amsawa da sauri, aiki mai santsi, tsawon rai, daidaiton matsayi mai girma (har zuwa ± 0.005mm)

Bayani

| Sunan Samfuri | Motar stepper mai haɗin gwiwa ta 57mm |

| Samfuri | VSM57BSHSM |

| Nau'i | Injinan stepper masu haɗin gwiwa |

| Kusurwar Mataki | 1.8° |

| Wutar lantarki (V) | 2.3 / 3 / 3.1 / 3.8 |

| Na yanzu (A) | 3/4 |

| Juriya (Ohms) | 0.75 / 1 / 0.78 / 0.95 |

| Inductance (mH) | 2.5 / 4.5 / 3.3 / 4.5 |

| Wayoyin Gubar | 4 |

| Tsawon Mota (mm) | 45 / 55 / 65 / 75 |

| Zafin Yanayi | -20℃ ~ +50℃ |

| Ƙara Zafin Jiki | Mafi girman 80K. |

| Ƙarfin Dielectric | Matsakaicin ƙarfin lantarki na 1mA @ 500V, 1KHz, Sec 1 |

| Juriyar Rufi | Minti 100MΩ @500Vdc |

Takaddun shaida

Sigogi na Lantarki:

| Girman Mota | Wutar lantarki /Mataki (V) | Na yanzu /Mataki (A) | Juriya /Mataki (Ω) | Inductance /Mataki (mH) | Adadin Wayoyin Gubar | Rotor Inertia (g.cm)2) | Nauyin Mota (g) | Tsawon Mota L (mm) |

| 57 | 2.3 | 3 | 0.75 | 2.5 | 4 | 150 | 580 | 45 |

| 57 | 3 | 3 | 1 | 4.5 | 4 | 300 | 710 | 55 |

| 57 | 3.1 | 4 | 0.78 | 3.3 | 4 | 400 | 880 | 65 |

| 57 | 3.8 | 4 | 0.95 | 4.5 | 4 | 480 | 950 | 75 |

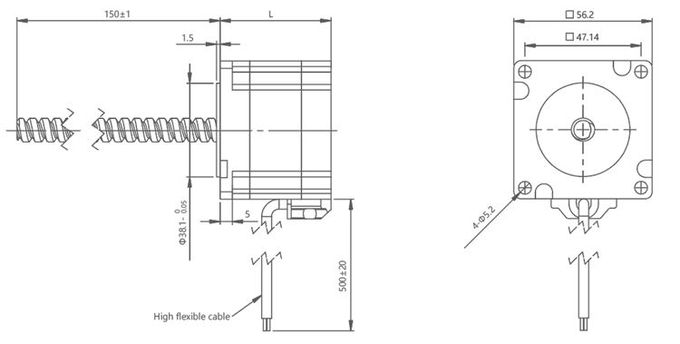

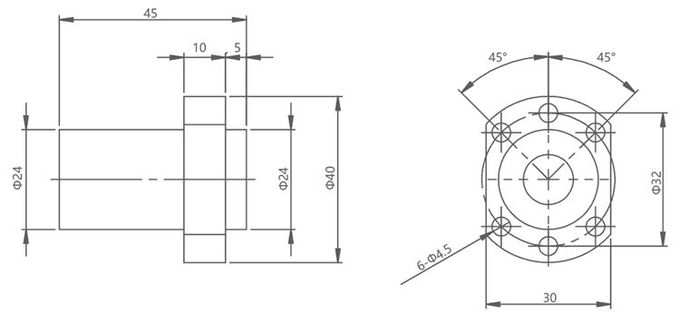

Tsarin zane na motar waje na misali na VSM57BSHSM:

Bayanan kula:

Za a iya keɓance tsawon sukurori na gubar

Injin da aka keɓance yana da amfani a ƙarshen sukurori na gubar

Da fatan za a tuntuɓe mu don ƙarin cikakkun bayanai game da sukurori.

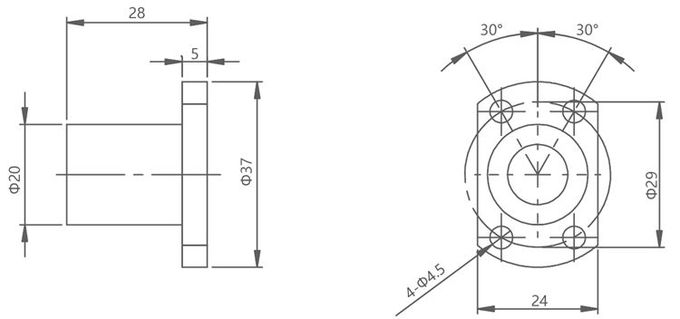

Zane mai siffar VSM57BSHSMBall goro 1202:

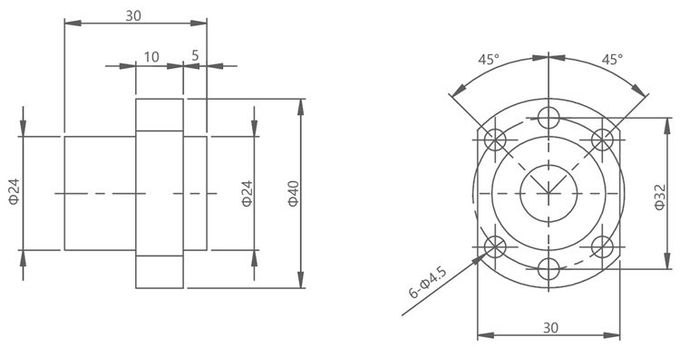

Zane mai siffar VSM57BSHSMBall goro 1205:

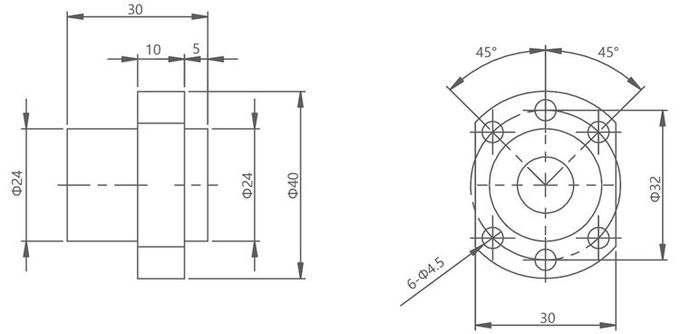

Zane mai siffar VSM57BSHSMBall goro 1210:

Zane mai siffar VSM57BSHSMBall goro 1210:

Gudun da lanƙwasa mai ƙarfi

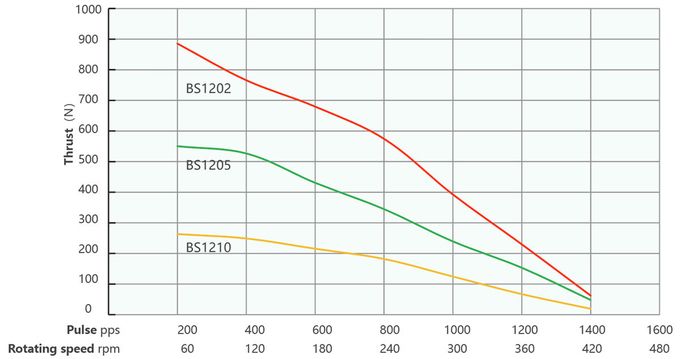

Motar Chopper mai tsawon mita 45mm mai jerin 57

Mitar bugun jini na yanzu 100% da kuma lanƙwasa na turawa

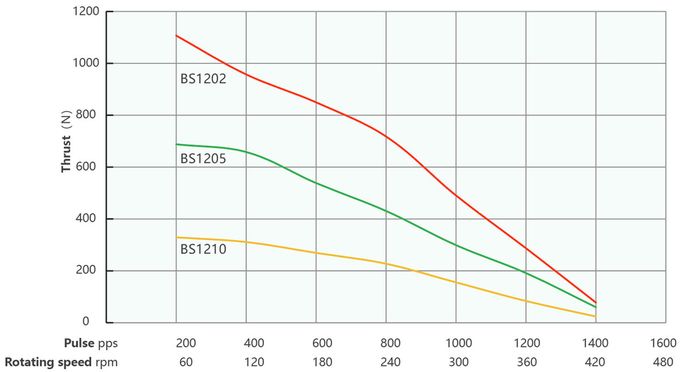

Motar Chopper mai tsawon mita 55mm mai jerin motoci 57

Mitar bugun jini na yanzu 100% da kuma lanƙwasa na turawa

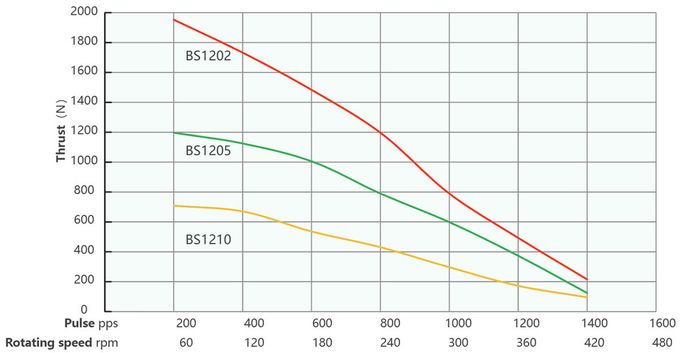

| Gubar (mm) | Gudun layi (mm/s) | |||||||

| 2 | 2 | 4 | 6 | 8 | 10 | 12 | 14 | 16 |

| 5 | 5 | 10 | 15 | 20 | 25 | 30 | 35 | 40 |

| 10 | 10 | 20 | 30 | 40 | 50 | 60 | 70 | 80 |

Yanayin gwaji:Tukin Chopper, babu tsalle-tsalle, rabin micro-stepping, ƙarfin tuƙi 40V

Motar Chopper mai tsawon mita 65mm mai jerin 57

Mitar bugun jini na yanzu 100% da kuma lanƙwasa na turawa

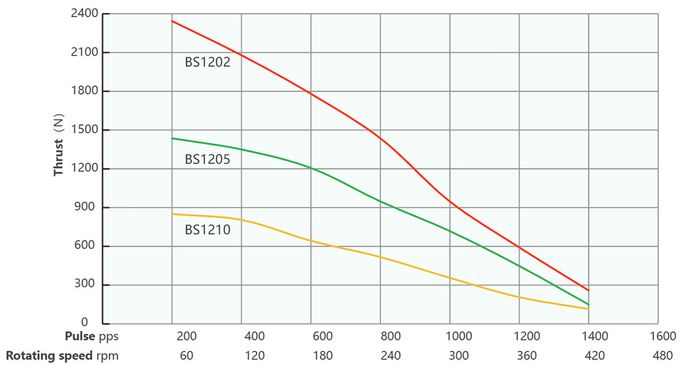

Motar Chopper mai tsawon mita 75mm mai jerin 57

Mitar bugun jini na yanzu 100% da kuma lanƙwasa na turawa

| Gubar (mm) | Gudun layi (mm/s) | |||||||

| 2 | 2 | 4 | 6 | 8 | 10 | 12 | 14 | 16 |

| 5 | 5 | 10 | 15 | 20 | 25 | 30 | 35 | 40 |

| 10 | 10 | 20 | 30 | 40 | 50 | 60 | 70 | 80 |

Yanayin gwaji:Tukin Chopper, babu tsalle-tsalle, rabin micro-stepping, ƙarfin tuƙi 40V

Yankunan aikace-aikace:

Kayan aikin ganewar asibiti:Ana iya amfani da injinan stepper na ƙwallo masu haɗaka na 57mm a cikin kayan aikin bincike na likita kamar na'urorin ɗaukar hoto, na'urorin ɗaukar hoto na CT, kayan aikin X-ray, kayan aikin MRI da sauransu. Tsarin kula da matsayi mai kyau da kwanciyar hankali yana ba da damar yin motsi da wuri daidai yayin ɗaukar hoto da sarrafa shi.

Kayan Aikin Kimiyyar Rayuwa:A cikin binciken kimiyya da gwaje-gwaje na rayuwa, ana amfani da injinan stepper na 57mm masu haɗaka a cikin tsarin sarrafa ruwa mai sarrafa kansa, kayan aikin tantancewa masu ƙarfi, na'urorin al'adar ƙwayoyin halitta, na'urorin jerin kwayoyin halitta, da ƙari. Babban daidaito da amincin waɗannan injinan yana ba su damar biyan buƙatun daidaitaccen motsi da sarrafa matsayi a cikin kayan aikin gwaji.

Fasahar Robobi:Ana amfani da injinan stepper na ƙwallon ƙwallo masu haɗin gwiwa na 57mm sosai a cikin na'urorin robot don haɗa hanyoyin, motsin hannu na robotic, da kuma daidaita matsayi. Waɗannan injinan suna da babban ƙarfin juyi, babban ƙuduri da ƙarancin hayaniya don biyan buƙatun daidaiton motsi da sarrafawa a aikace-aikacen robotic.

Kayan aikin Laser:Ana iya amfani da injinan stepper na ƙwallo masu haɗaka na 57mm a cikin kayan aikin laser don ayyuka kamar daidaita mayar da hankali, teburin panning, da kuma sarrafa hanyar gani. Kula da matsayi mai inganci da kwanciyar hankali yana ba shi damar cimma daidaiton mayar da hankali da matsayin hasken laser.

Kayan Aikin Nazari:A cikin nau'ikan kayan aikin bincike na dakin gwaje-gwaje daban-daban, ana iya amfani da injinan stepper na ƙwallo masu haɗin gwiwa na 57mm a cikin sarrafa samfura ta atomatik, tsarin ciyar da samfura, chromatographs na ruwa, chromatographs na gas, da sauransu. Motsi mai inganci da aiki mai karko na waɗannan injinan suna taka muhimmiyar rawa wajen inganta daidaito da ingancin nazarin dakin gwaje-gwaje.

Kayan aikin Semiconductor da kayan aikin samar da lantarki:Ana amfani da injinan stepper na ƙwallo masu haɗaka na 57mm don daidaita matsayi da sarrafa kansa a cikin kayan aikin semiconductor da na lantarki. Misali, ana iya amfani da su a cikin kayan gwajin guntu na semiconductor, injunan marufi, fasahar hawa saman, kera allon da'ira da aka buga da sauran wurare don samar da ingantaccen iko na motsi mai sauri, daidaito da aminci.

Kayan aikin sarrafa kansa marasa tsari da nau'ikan kayan aikin sarrafa kansa daban-daban:Injinan stepper na ƙwallo masu haɗaka na 57mm sun dace da nau'ikan kayan aiki na atomatik marasa daidaito da layukan samarwa ta atomatik. Ana iya amfani da su a cikin kayan aiki na sanyawa, tsarin haɗawa ta atomatik, kayan marufi, injinan bugawa, kayan yadi, da sauransu. Suna ba da daidaitaccen sarrafa matsayi da ingantaccen aikin motsi don biyan buƙatun sarrafa kansa a fannoni daban-daban.

Riba

Babban Rabon Karfin Juyawa zuwa Rashin Inertia:Motocin stepper na ƙwallo masu haɗaka suna da babban rabo na juyi-zuwa-inertia, wanda ke nufin suna iya isar da gagarumin fitarwa na juyi dangane da girmansu da nauyinsu. Wannan ya sa suka dace da aikace-aikacen da ke buƙatar babban juyi a cikin ƙaramin tsari, kamar na'urorin robot, injunan CNC, da tsarin sarrafa kansa.

Babban Sauri da Rage Ragewa:Waɗannan injinan suna da ikon hanzartawa da rage gudu cikin sauri, wanda ke ba da damar yin motsi cikin sauri da daidaito. Ƙarancin ƙarfin lantarki na rotor da kuma ƙarfin juyi mai yawa yana ba motar damar amsawa da sauri ga siginar sarrafawa, wanda ke haifar da saurin lokacin farawa da tsayawa da kuma inganta aikin tsarin gabaɗaya.

Sanyi mai laushi na Microstepping:Motocin stepper na ƙwallo masu haɗaka sun dace sosai don aikin microstepping, wanda ke ba da damar ƙuduri mai kyau da kuma sarrafa motsi mai santsi. Microstepping yana raba kowane cikakken mataki zuwa ƙananan ƙananan matakai, yana rage girman mataki da rage girgiza, hayaniya, da tasirin resonance. Wannan fasalin yana da amfani musamman a aikace-aikacen da ke buƙatar motsi mai santsi da daidaito, kamar firintocin 3D da tsarin sanya layi.

Ƙananan baya:Tsarin sukurori na ƙwallo a cikin waɗannan injinan yana taimakawa wajen rage koma-baya, wanda shine wasa ko sharewa tsakanin rotor da kaya. Ƙananan koma-baya yana tabbatar da daidaiton matsayi da maimaitawa, saboda akwai ƙarancin motsi da aka rasa lokacin canza alkibla ko juyawar motsi. Wannan yana da mahimmanci ga aikace-aikacen da ke buƙatar daidaito da kuma maimaituwa matsayi, kamar injinan ɗauka da sanyawa da tsarin gani.

Babban Amsar Canji:Haɗin injin stepper mai haɗaka da tsarin sukurori na ƙwallo yana ba da damar samun babban amsawa mai ƙarfi, ma'ana injin zai iya bin canje-canje a cikin siginar sarrafawa cikin sauri da daidai. Wannan amsawar yana da mahimmanci ga aikace-aikacen da suka haɗa da canje-canje cikin sauri, alkibla, ko matsayi, kamar injinan aiki mai sauri da tsarin sarrafa motsi mai ƙarfi.

Ingantaccen Zafi:An ƙera injinan stepper na ball sukurori masu haɗaka don samun ingantaccen ingancin zafi, wanda ke ba da damar watsa zafi mai inganci yayin aiki. Wannan yana taimakawa hana zafi sosai kuma yana tabbatar da ingantaccen aikin injin, koda a lokacin amfani da shi na dogon lokaci ko kuma a lokacin aikace-aikacen da ke buƙatar aiki.

Maganin Ingantaccen Farashi:Injinan stepper na ƙwallo masu haɗaka suna ba da mafita mai inganci ga aikace-aikacen da ke buƙatar babban daidaito da ƙarfin juyi. Idan aka kwatanta da tsarin injin servo masu rikitarwa da tsada, injinan stepper na haɗin gwiwa suna ba da daidaito tsakanin aiki, farashi, da sauƙin amfani. Sau da yawa su ne zaɓin da aka fi so don aikace-aikace inda farashi yake da mahimmanci, ba tare da yin la'akari da inganci da aiki ba.

Bukatun Zaɓin Mota:

► Hanyar motsi/hawa

► Bukatun Load

► Bukatun bugun jini

► Bukatun kayan aiki na ƙarshe

► Bukatun Daidaito

► Bukatun Ra'ayoyin Mai Rubutawa

► Bukatun Gyara da Hannu

► Bukatun Muhalli

Bitar samarwa