NEMA34 86mm Linear hybrid stepper motor external drive high push

Bayani

Motar stepper ta NEMA 34 mai haɗaka tana da girman 86mm.

Haka kuma motar stepper mai layi ta waje ce mai tsawon 135mm mai shaft ɗin sukurori na gubar a samanta, kuma tana da goro/zamewar filastik da ta dace da ita.

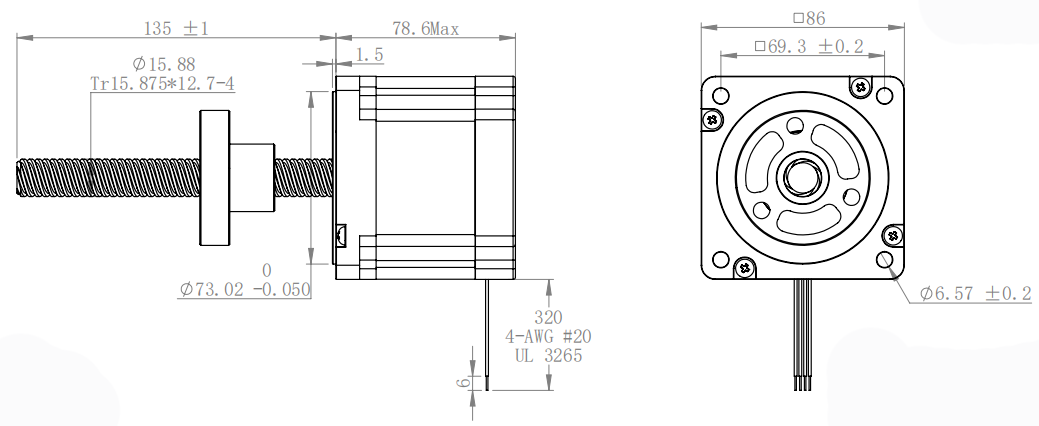

Lambar samfurin: Tr15.875*P3.175*4N

Girman sukurorin gubar shine 3.17mm, kuma yana da farawa 4, don haka gubar = lambar farawa * firam ɗin sukurori na gubar = 4 * 3.175mm = 12.7mm

Don haka tsawon matakin motar shine: 12.7mm/matakai 200=0.0635mm/mataki

Muna da wasu nau'in sukurori na gubar don zaɓuɓɓuka, ya dogara da buƙatun abokin ciniki akan tururin motar da saurin layi.

Sigogi

| Lambar Samfura | SM86C0905 |

| Diamita na injin | 86mm (NEMA34) |

| Ƙarfin tuƙi | 5V DC |

| Juriyar na'ura | 1.6Ω±10%/mataki |

| Adadin mataki | Matakai 2(bipolar) |

| Kusurwar mataki | 1.8°/mataki |

| Darajar halin yanzu | 3.12A/mataki |

| Mafi ƙarancin ƙarfin turawa (300PPS) | 50KG |

| Tsawon mataki | 0.0635mm/mataki |

Sigar siginar gubar

| Nau'in sukurori na gubar | Sukurin trapezoidal |

| Samfurin sukurori | Tr15.875*P3.175*4N |

| Diamita na waje | 15..875 mm |

| Jagora | 12.7mm |

| Farawa | 4 |

| Fitilar wasa | 3.175mm |

| Tsawon mataki | 0.0635mm/mataki |

Zane Zane

Game da sukurori na gubar

Sukurin jagora da ake amfani da shi a kan injin stepper mai layi yana cikin sukurin jagora na trapezoidal gabaɗaya.

Misali ga sukurorin gubar Tr3.5*P0.3*1N.

Tr yana nufin nau'in sukurori na jagora na trapezoidal

P0.3 yana nufin girman sukurori na gubar shine 0.3mm

1N yana nufin sukurori ɗaya na farko.

Jagoran sukurori na jagora = lambar farawa * filin wasa

Don haka ga wannan takamaiman sukurori na gubar, yana da gubar 0.3mm.

Kusurwar stepper ta motar hybrid stepper ita ce digiri 1.8/mataki, wanda ke ɗaukar matakai 200 don juyawa ɗaya.

Tsawon mataki shine motsi mai layi wanda injin yake yi, idan ya ɗauki mataki ɗaya.

Ga sukurori mai nauyin 0.3mm, tsawon matakin shine 0.3mm/200 mataki = 0.0015mm/mataki

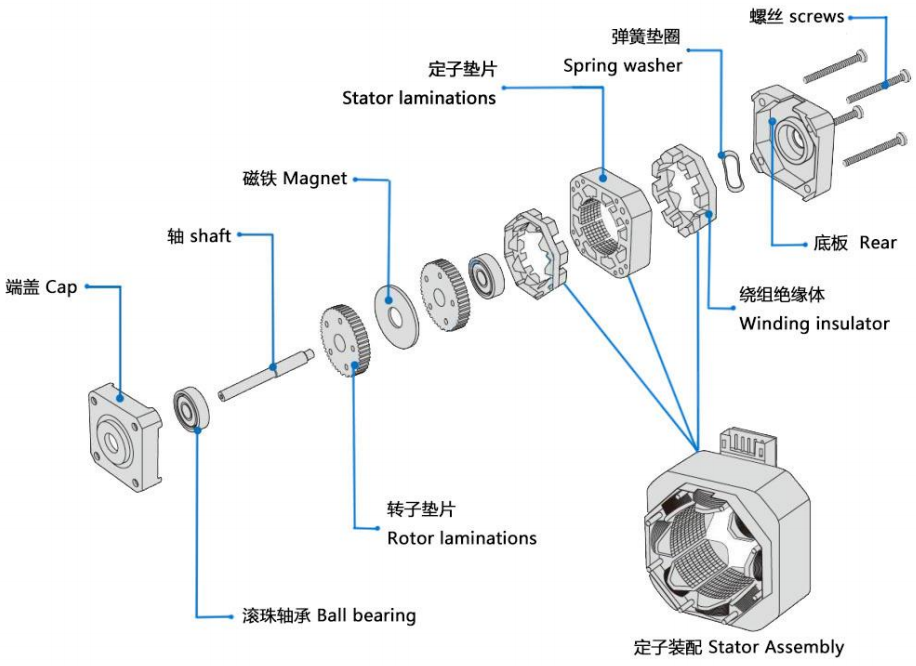

Tsarin asali na injinan stepper na NEMA

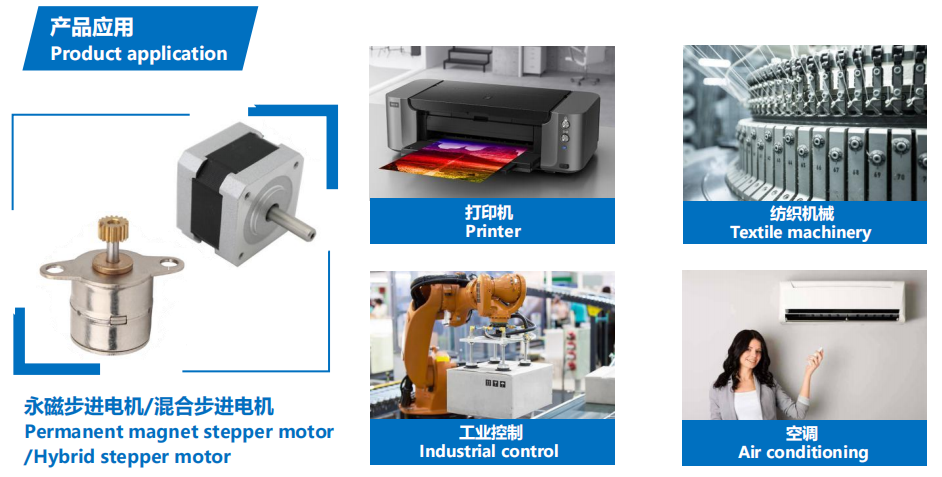

Amfani da Hybrid stepper motor

Saboda ƙudurin ƙarfin injin stepper na hybrid (matakai 200 ko 400 a kowace juyi), ana amfani da su sosai don aikace-aikacen da ke buƙatar babban daidaito, kamar:

Bugawa ta 3D

Sarrafa Masana'antu (CNC, injin niƙa ta atomatik, injinan yadi)

Kayan aikin kwamfuta

Injin shiryawa

Da kuma sauran tsarin atomatik da ke buƙatar cikakken iko.

Ya kamata abokan ciniki su bi ƙa'idar "zaɓar injinan stepper da farko, sannan a zaɓi direba bisa ga injin stepper da ke akwai"

Zai fi kyau kada a yi amfani da yanayin tuƙi mai cikakken mataki don tuƙa motar takalmi mai haɗaka, kuma girgizar ta fi girma a ƙarƙashin tuƙi mai cikakken mataki.

Motar stepper mai haɗaka ta fi dacewa da lokutan ƙarancin gudu. Muna ba da shawarar cewa gudun bai wuce rpm 1000 ba (6666PPS a digiri 0.9), zai fi dacewa tsakanin digiri 1000-3000PPS (digiri 0.9), kuma ana iya haɗa shi da akwatin gear don rage saurinsa. Motar tana da ingantaccen aiki da ƙarancin hayaniya a mitar da ta dace.

Saboda dalilai na tarihi, injin da ke da ƙarfin lantarki na 12V kawai yana amfani da 12V. Sauran ƙarfin lantarki da aka ƙididdige akan zane ba shine ainihin ƙarfin lantarki mafi dacewa ga motar ba. Abokan ciniki ya kamata su zaɓi ƙarfin lantarki mai dacewa da direba mai dacewa bisa ga buƙatunsu.

Idan ana amfani da injin tare da babban gudu ko babban kaya, yawanci ba ya farawa da saurin aiki kai tsaye. Muna ba da shawarar a hankali ƙara mita da gudu. Saboda dalilai biyu: Na farko, injin ba ya rasa matakai, na biyu kuma, yana iya rage hayaniya da inganta daidaiton wurin aiki.

Bai kamata injin ya yi aiki a yankin girgiza ba (ƙasa da 600 PPS). Idan dole ne a yi amfani da shi a hankali, za a iya rage matsalar girgiza ta hanyar canza ƙarfin lantarki, wutar lantarki ko ƙara ɗan damping.

Idan injin yana aiki ƙasa da digiri 600 (0.9), ya kamata ya kasance ƙarƙashin ƙaramin wutar lantarki, babban inductance da ƙarancin wutar lantarki.

Ga kayan aiki masu yawan inertia, ya kamata a zaɓi babban injin.

Idan ana buƙatar ƙarin daidaito, ana iya magance shi ta hanyar ƙara akwatin gearbox, ƙara saurin motar, ko amfani da tuƙin yanki. Haka kuma ana iya amfani da injin mai matakai 5 (motar unipolar), amma farashin tsarin gaba ɗaya yana da tsada sosai, don haka ba kasafai ake amfani da shi ba.

Girman motar stepper:

A halin yanzu muna da injinan stepper masu haɗin gwiwa na 20mm (NEMA8), 28mm (NEMA11), 35mm (NEMA14), 42mm (NEMA17), 57mm (NEMA23), 86mm (NEMA34). Muna ba da shawarar a fara tantance girman injin, sannan a tabbatar da wasu sigogi, lokacin da kuka zaɓi injin stepper mai haɗin gwiwa.

Sabis na keɓancewa

Za a iya daidaita ƙirar motar bisa ga buƙatun abokin ciniki, gami da:

Diamita na motar: muna da injin diamita 6mm, 8mm, 10mm, 15mm da 20mm

Juriyar Coil/ ƙimar ƙarfin lantarki: juriyar coil za a iya daidaitawa, kuma tare da juriya mafi girma, ƙimar ƙarfin lantarki na injin ya fi girma.

Tsarin maƙallin/tsawon sukurori na gubar: idan abokin ciniki yana son maƙallin ya zama mai tsayi/gajere, tare da ƙira ta musamman kamar ramukan hawa, ana iya daidaitawa.

Kebul na PCB + + mahaɗi: Tsarin PCB, tsawon kebul da kuma sautin mahaɗin duk ana iya daidaita su, ana iya maye gurbinsu da FPC idan abokan ciniki suka buƙata.

Lokacin Gabatarwa

Idan muna da samfura a hannun jari, za mu iya jigilar samfuran cikin kwana 3.

Idan ba mu da samfura a hannun jari, muna buƙatar samar da su, lokacin samarwa shine kimanin kwanaki 20 na kalanda.

Don samar da taro, lokacin jagora ya dogara da adadin oda.

Hanyar biyan kuɗi da sharuɗɗan biyan kuɗi

Ga samfurori, gabaɗaya muna karɓar Paypal ko alibaba.

Don samar da kayayyaki da yawa, muna karɓar biyan kuɗi na T/T.

Don samfurori, muna karɓar cikakken biyan kuɗi kafin samarwa.

Don samar da kayayyaki da yawa, za mu iya karɓar kashi 50% na kuɗin da aka biya kafin a samar, sannan mu karɓi sauran kashi 50% na kuɗin kafin a kawo.

Bayan mun yi aiki tare da oda fiye da sau 6, za mu iya yin shawarwari kan wasu sharuɗɗan biyan kuɗi kamar A/S (bayan gani)

Tambayoyin da ake yawan yi akai-akai

1. Har yaushe ne lokacin isar da samfura gabaɗaya? Har yaushe ne lokacin isar da manyan oda na baya-baya?

Lokacin isar da samfurin yana ɗaukar kimanin kwanaki 15, lokacin isar da umarni na adadi mai yawa shine kwanaki 25-30.

2. Shin kuna karɓar sabis na musamman?

Muna karɓar samfuran da aka ƙera musamman. gami da sigar mota, nau'in waya mai gubar, shaft mai fita da sauransu.

3. Shin zai yiwu a ƙara lambar sirri a cikin wannan injin?

Don wannan nau'in motar, za mu iya ƙara lambar sirri a kan murfin lalacewa na motar.

Tambayar da Ake Yawan Yi

1. Menene bambanci tsakanin wayoyi masu motsi biyu (bipolar) da kuma wayoyi marasa motsi (unipolar) na injinan stepper?

Injinan Stepper masu haɗin bipolar suna amfani da hanyar tuƙi inda kwararar wutar lantarki ke gudana a duka kwatancen a cikin naɗewa ɗaya (bipolar drive).

Motar stepper mai haɗin sanda ɗaya tana da famfo na tsakiya kuma tana amfani da hanyar tuƙi inda wutar lantarki koyaushe ke gudana a cikin madaidaicin alkibla a cikin naɗewa ɗaya (tuƙi mai sanda ɗaya).

2. Motar Stepper a yanayin aiki na farawa-tsayawa ba za ta iya fara dalilai da hanyoyin sarrafawa ba

a.load ya yi girma sosai: kuskuren zaɓin mota, zaɓi girman motar da ya fi girma.

b.mita ya yi yawa: rage mitar

c. Idan motar tana juyawa baya da baya, ko kuma karfin juyi ya yi karami sosai, wanda ke nuna cewa akwai lalacewar mataki, ko kuma da'irar da ta karye: maye gurbin ko gyara motar

d. Tsarin wutar lantarki bai isa ba: Ƙara ƙarfin wutar lantarki na lokaci, aƙalla don matakai kaɗan na farko na farawa

3. Halaye da mafita ga injinan stepper waɗanda ke kammala hanzari amma suna daina juyawa idan sun kai ga saurin da ya dace.

Dalili: Motar stepper tana aiki a iyakar ƙarfinta kuma tana tsayawa saboda yawan hanzari. Rotor yana girgiza kuma yana aiki ba tare da tsayawa ba.

Mafita.

①Rage hanzari, wato zaɓi ƙaramin hanzari ko amfani da matakai biyu daban-daban na hanzari, mafi girma a farkon da ƙasa kusa da matsakaicin gudu.

②Ƙara ƙarfin juyi

③Ƙara damper na injiniya a kan shaft na baya, amma wannan yana ƙara ƙarfin juyawar rotor

④ Yi amfani da hanyar haɗin gwiwa