Tare da saurin haɓaka aikin sarrafa masana'antu da masana'antu na fasaha, injiniyoyin stepper na matasan sun zama a hankali a hankali abubuwan tuki a fagen sarrafa madaidaici saboda fa'idodin aikinsu na musamman. Wannan labarin yana ba da zurfin bincike game da ƙa'idar aiki, fa'idodi na yau da kullun, da yanayin aikace-aikacen al'ada na injunan stepper matasan, yana taimaka wa masu karatu su fahimci ƙimar wannan fasaha a masana'antar zamani.

一,Fasaha abũbuwan amfãni daga matasan stepper Motors

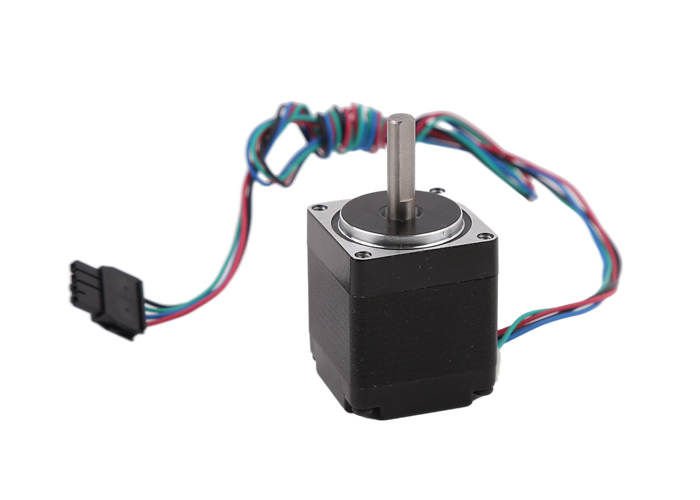

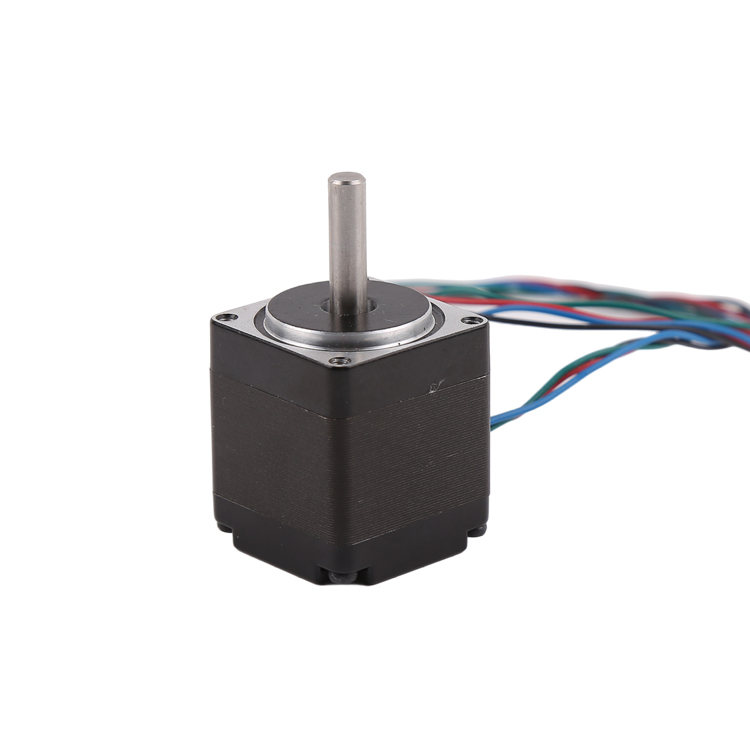

Motar stepper mai matasan ya haɗu da halayen ƙira na dindindin magnet stepper motor (PM) da m stepper motor (VR), kuma ya cimma manyan fa'idodi masu zuwa ta haɓaka tsarin da'irar maganadisu da hanyar sarrafawa:

1. Babban madaidaicin matsayi da sarrafawa

The matasan stepper motor rungumi dabi'ar subdivision drive fasahar, wanda zai iya raba guda mataki kwana zuwa micro mataki matakin (kamar 0.9 ° mataki kwana iya isa 0.0035 ° ta 256 subdivision), saduwa da m bukatun na daidaici kayan aiki don matsayi iko da kuma dace da high-madaidaici al'amura kamar 3D inji kayan aikin da CNC bugu.

2. Babban fitarwa da kwanciyar hankali

Ta amfani da rare duniya m maganadisu kayan da inganta winding zane, matasan stepper Motors iya kula da high karfin juyi fitarwa a low gudu tare da kadan karfin juyi hawa da sauka, guje wa matsalar "fita daga mataki" lalacewa ta hanyar load canje-canje a cikin gargajiya Motors da muhimmanci inganta tsarin AMINCI.

3. Energy ceton da low dumama halaye

Idan aka kwatanta da na'urorin motsa jiki na yau da kullun, ƙirar matasan tana rage asarar tagulla da baƙin ƙarfe, kuma tare da fasahar sarrafa madauki, yana iya ƙara rage yawan kuzari, rage yawan zafin jiki na dogon lokaci, da tsawaita rayuwar sabis na kayan aiki.

4. Amsa mai sauri da sarrafawa mai sassauci

Za a iya samun ikon sarrafa madauki ba tare da buƙatar tsarin amsa mai rikitarwa ba, yana goyan bayan siginar siginar bugun jini kai tsaye, tare da gajeren lokacin amsawa (matakin millisecond), kuma ana iya daidaita shi da sauƙi ga masu sarrafawa daban-daban kamar PLC da microcontroller.

5. Karfin daidaita yanayin muhalli

Matsayin kariya zai iya kaiwa IP65, tare da matsanancin zafin jiki, juriya na ƙura, da juriya na girgiza, dace da yanayin aiki mai rikitarwa kamar tarurrukan masana'antu da kayan aikin likita.

二,Core aikace-aikace yankunan na matasan stepper Motors

1. Kayan aikin sarrafa kansa na masana'antu

Kayan aikin injin CNC da makamai na robotic: ana amfani da su don ingantaccen sarrafa motsi kamar saka kayan aiki da matsi na aiki.

Injin Marufi: Sarrafa saurin gudu da matsayi na bel mai ɗaukar nauyi don haɓaka ingantaccen layin samarwa.

Masana'antar Semiconductor: Fitar da injunan yankan wafer da injunan rarrabawa don tabbatar da daidaiton matakin sarrafa matakin micrometer.

2. Kayan aikin likita da dakin gwaje-gwaje

Tsarin hoto na likitanci: CT na'urar daukar hotan takardu, jujjuyawar dandamali don injin X-ray.

Mai nazarin kwayoyin halitta: Daidaita sarrafa motsi na reagent bincike don rage haɗarin gurɓataccen samfurin.

Robot na tiyata: Yana ba da tabbataccen martanin ƙarfi da sarrafa motsin haɗin gwiwa.

3. Mabukaci Electronics da smart hardware

Firintar 3D: Sarrafa motsi na 3D na shugaban bugu da dandamali don tabbatar da daidaiton kauri.

Tsaro mai hankali: Fitar da kyamarar kwanon rufi don cimma daidaiton saka idanu na 360 °.

Aikin ofis: tsarin ciyar da takarda don masu kwafi da na'urar daukar hoto.

4. Sabbin motocin makamashi da sararin samaniya

A cikin kayan aikin mota: daidaitaccen wurin zama na lantarki, tsarin kulle tari na caji.

Drones da robots: sarrafa servo, matsayi na rotor, haɓaka kwanciyar hankali na jirgin.

eriyar tauraron dan adam: samun babban madaidaicin nuni da bin diddigi.

5. Kare makamashi da makamashi mai sabuntawa

Tsarin bin diddigin hasken rana:Daidaita jagorancin bangarori na hotovoltaic ta atomatik dangane da kusurwar haske don inganta ƙarfin samar da wutar lantarki.

Gidan Smart:Maganin Tutar Silent don Labulen Lantarki da Makullin Ƙofar Smart.

三,A nan gaba ci gaban Trend na matasan stepper Motors

Tare da yaɗawar Intanet na Abubuwa (IoT) da fasaha na fasaha na wucin gadi, injinan stepper na matasan suna haɓaka ta hanyoyi masu zuwa:

Haɗin kai:Gina cikin guntuwar direba da tsarin sadarwa (kamar CAN bas EtherCAT) , Sauƙaƙe tsarin wayoyi.

Hankali:Ana samun amsawar madauki ta hanyar na'urori masu auna firikwensin don rama kurakuran matsayi ta atomatik.

Miniaturization:Haɓaka ƙananan injuna masu diamita ƙasa da 20mm don biyan buƙatun na'urori masu ɗaukuwa.

Green Manufacturing:Ɗauki kayan da za a sake amfani da su da ƙira mai ƙarancin ƙarfi, daidai da manufofin tsaka-tsakin carbon na duniya.

四,Yadda za a zabi wani dace matasan stepper motor?

Kamfanoni suna buƙatar yin la'akari da sigogi masu zuwa gabaɗaya yayin zabar samfura:

Bukatar karfin wuta:Ƙirƙirar juzu'i kololuwa da riƙon juzu'i dangane da rashin kuzari.

Daidaiton kusurwar mataki:0.9 ° ko 1.8 ° mataki kusurwa, haɗe tare da direban yanki don daidaita ƙuduri.

Voltage da halin yanzu:Daidaita ƙarfin fitarwa na direba don guje wa zazzaɓi ko rashin isasshen wuta.

Matakin kariya:Ya kamata a zaɓi samfuran IP65 ko sama don yanayin waje ko ɗanɗano.

Farashin da tsawon rayuwa:Daidaita farashin sayayya na farko tare da kuɗin kulawa na dogon lokaci.

五,ƙarshe

A matsayinsa na "buyayyen zakara" a fagen sarrafa motsin motsi, matasan stepper Motors suna ci gaba da ƙarfafa masana'antun fasaha, fasahar likitanci, da masana'antun makamashi na kore tare da babban farashi, kwanciyar hankali, da aminci. Tare da haɓakawa da haɓaka fasaha, yanayin aikace-aikacen sa zai ƙara faɗaɗa kuma ya zama babban abin da ke motsa tsarin masana'antu 4.0. Ta hanyar zaɓi na hankali da haɗin kai na tsarin, kamfanoni na iya haɓaka aikin kayan aiki sosai, rage farashin aiki da kulawa, da samun fa'ida a gasar kasuwa.

Lokacin aikawa: Mayu-15-2025