A fannin kera na'urorin lantarki masu sauri da inganci, na'urorin gwajin allurar lantarki suna aiki a matsayin masu tsaron ƙofa waɗanda ke tabbatar da ingancin PCBs, chips, da modules. Yayin da tazara tsakanin sassan ke ƙara ƙanƙanta kuma sarkakiyar gwaji ke ƙaruwa, buƙatun daidaito da aminci a gwaji sun kai kololuwar da ba a taɓa gani ba. A cikin wannan juyin juya halin auna daidaito, ƙananan injinan stepper suna taka muhimmiyar rawa a matsayin "masu daidaita tsokoki". Wannan labarin zai bincika yadda wannan ƙaramin ƙarfin lantarki ke aiki daidai a cikin na'urorin gwajin allurar lantarki, yana tura gwajin lantarki na zamani zuwa wani sabon zamani.

一.Gabatarwa: Lokacin da ake buƙatar daidaiton gwaji ya kasance a matakin micron

Hanyoyin gwaji na gargajiya sun zama marasa dacewa ga buƙatun gwaji na fakitin BGA, QFP, da CSP na yau. Babban aikin adaftar gwajin allurar lantarki shine tuƙa dubban na'urori masu gwaji don kafa ingantattun haɗin jiki da na lantarki tare da wuraren gwaji akan na'urar da ake gwadawa. Duk wani ƙaramin kuskure, matsin lamba mara daidaituwa, ko hulɗa mara daidaituwa na iya haifar da gazawar gwaji, rashin fahimtar juna, ko ma lalacewar samfura. Injinan micro stepper, tare da ikon sarrafa dijital na musamman da halayensu masu inganci, sun zama mafita mafi kyau don magance waɗannan ƙalubalen.

一.Tsarin aiki na injin micro stepper a cikin adaftar

Aikin ƙaramin injin stepper a cikin adaftar gwajin allurar lantarki ba juyawa ce mai sauƙi ba, amma jerin motsi masu daidaito da kuma sarrafawa. Ana iya raba aikin sa zuwa manyan matakai masu zuwa:

1. Daidaito daidai da kuma wurin da aka fara

Tsarin aiki:

Umarnin karɓa:Kwamfutar mai masaukin baki (mai masaukin gwaji) tana aika bayanan daidaitawa na ɓangaren don a gwada shi zuwa katin sarrafa motsi, wanda ke mayar da shi zuwa jerin siginar bugun jini.

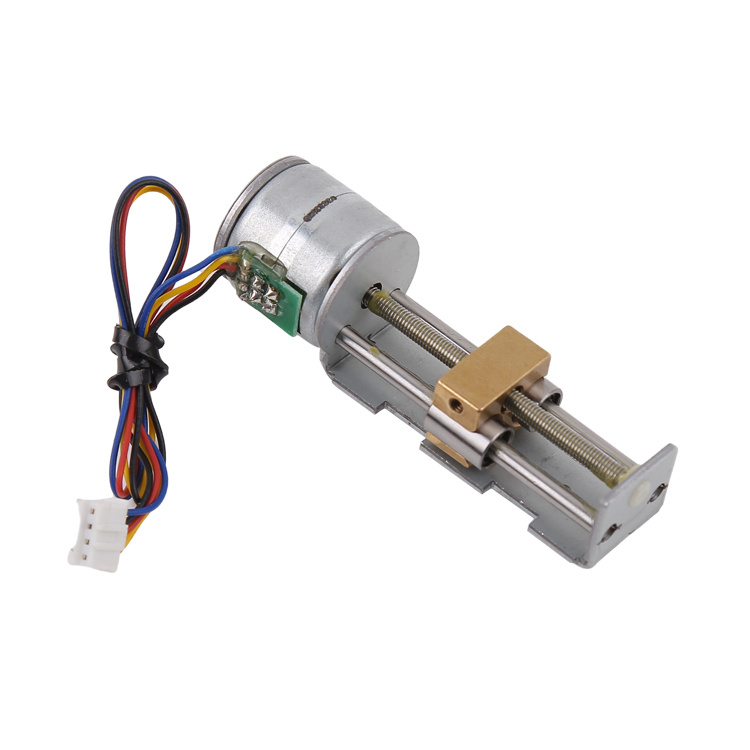

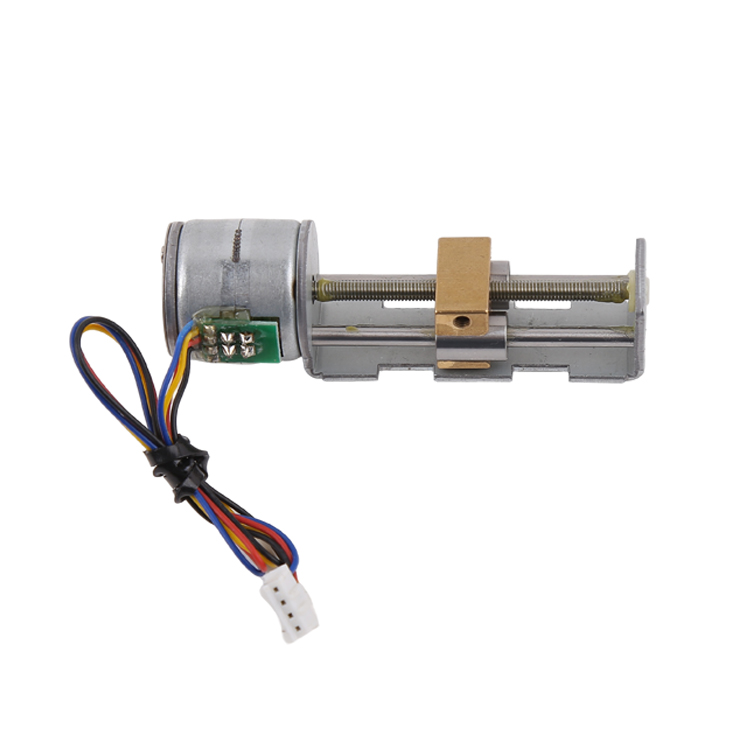

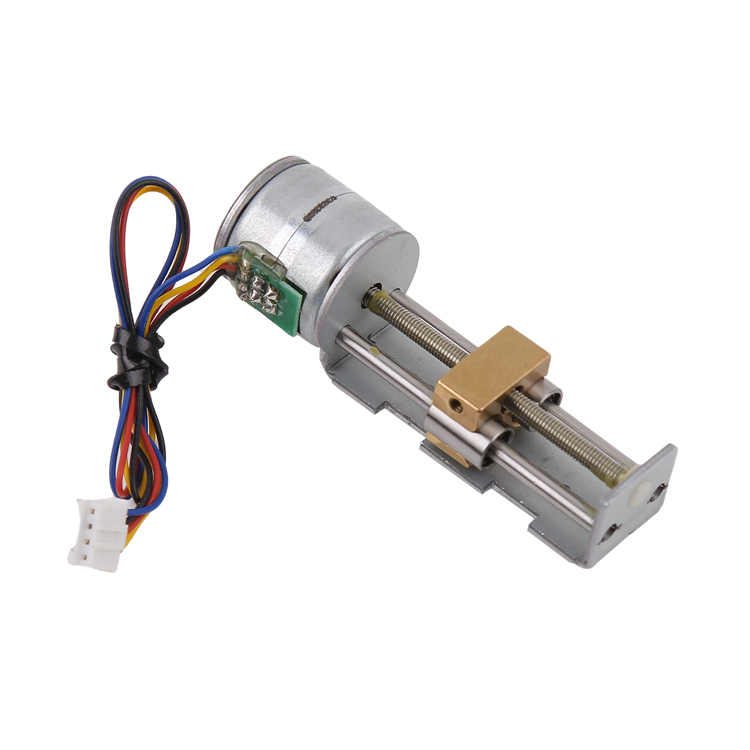

Motsin juyawar bugun jini:Ana aika waɗannan siginar bugun jini zuwa ga direban injin ƙaramin stepper. Kowace siginar bugun jini tana tura shaft ɗin motar don juya kusurwar da aka saita - "kusurwar mataki". Ta hanyar fasahar tuƙin microstepping mai ci gaba, ana iya raba kusurwar matakai gaba ɗaya zuwa ƙananan steps 256 ko ma fiye, don haka cimma nasarar sarrafa matakin micrometer ko ma matakin submicrometer.

Matsayin aiwatarwa:Injin, ta hanyar hanyoyin watsawa kamar sukurori masu daidaito ko bel ɗin lokaci, yana tuƙa karusar da aka ɗora da na'urorin gwaji don motsawa akan jiragen X-axis da Y-axis. Tsarin yana motsa jerin na'urorin bincike daidai zuwa matsayin da ke sama da wurin da za a gwada ta hanyar aika takamaiman adadin bugun jini.

2. Gudanar da matsi da matsin lamba da aka sarrafa

Tsarin aiki:

Kimanin axis na Z:Bayan kammala wurin da jirgin yake, ƙaramin injin stepper wanda ke da alhakin motsi na Z-axis zai fara aiki. Yana karɓar umarni kuma yana tura dukkan kan gwaji ko wani ɓangaren bincike guda ɗaya don motsawa tsaye zuwa ƙasa tare da axis na Z.

Daidaitaccen tsarin tafiyar tafiya:Motar tana matsawa ƙasa cikin sauƙi a cikin ƙananan matakai, tana sarrafa nisan tafiya na injin latsawa daidai. Wannan yana da mahimmanci, domin ɗan gajeren tafiya zai iya haifar da rashin hulɗa mai kyau, yayin da nisan tafiya mai tsawo zai iya matse maɓuɓɓugar binciken, wanda ke haifar da matsin lamba mai yawa da lalacewa ga maƙullin solder.

Kula da Juyin Juya Halin Ƙarfi Don Dore Matsi:Idan na'urar binciken ta kai zurfin hulɗar da aka saita tare da wurin gwaji, injin ƙaramin stepper zai daina juyawa. A wannan lokacin, injin, tare da ƙarfin riƙewa mai ƙarfi, zai kasance a kulle a wurinsa, yana kiyaye ƙarfin saukarwa mai ɗorewa kuma mai aminci ba tare da buƙatar ci gaba da samar da wutar lantarki ba. Wannan yana tabbatar da kwanciyar hankali na haɗin lantarki a duk tsawon zagayen gwaji. Musamman ga gwajin sigina mai yawan mita, haɗin injina mai ɗorewa shine tushen amincin sigina.

3. Dubawa mai maki da yawa da gwajin hanya mai rikitarwa

Tsarin aiki:

Ga PCB masu rikitarwa waɗanda ke buƙatar gwajin abubuwan da aka haɗa a wurare daban-daban ko kuma a tsayi daban-daban, masu adafta suna haɗa injinan stepper da yawa don samar da tsarin motsi mai yawa.

Tsarin yana daidaita motsin injina daban-daban bisa ga jerin gwaje-gwajen da aka riga aka tsara. Misali, da farko yana gwada Yankin A, sannan injinan XY suna motsawa cikin haɗin kai don motsa jerin binciken zuwa Yankin B, kuma injin Z-axis yana sake dannawa don gwaji. Wannan yanayin "gwajin tashi" yana inganta ingancin gwaji sosai.

A cikin dukkan tsarin, ainihin ƙarfin ƙwaƙwalwar wurin injin yana tabbatar da maimaita daidaiton matsayi ga kowane motsi, yana kawar da kurakurai masu tarin yawa.

一.Me yasa za a zaɓi injinan stepper na micro? - Fa'idodi a bayan tsarin aiki

Tsarin aiki na ainihi da aka ambata ya samo asali ne daga halayen fasaha na injin stepper na micro da kansa:

Tsarin Dijital da Daidaita Pulse:Matsayin injin yana da daidaito sosai tare da adadin bugun shigarwa, wanda ke ba da damar haɗa kai ba tare da matsala ba tare da kwamfutoci da PLCs don cikakken iko na dijital. Zaɓi ne mai kyau don gwaji ta atomatik.

Babu wani kuskuren tarawa:A ƙarƙashin yanayin rashin ɗaukar nauyi, kuskuren matakan motar stepper ba ya taruwa a hankali. Daidaiton kowane motsi ya dogara ne kawai akan aikin motar da direba, wanda ke tabbatar da aminci don gwaji na dogon lokaci.

Tsarin ƙarami da yawan ƙarfin juyi mai yawa:Ƙaramin ƙirar yana ba da damar shigar da shi cikin sauƙi a cikin ƙananan kayan gwaji, yayin da yake samar da isasshen ƙarfin juyi don tuƙi jerin binciken, yana cimma daidaito mai kyau tsakanin aiki da girma.

一.Magance Kalubale: Fasaha don Inganta Ingancin Aiki

Duk da fa'idodin da ke tattare da shi, a aikace-aikace, ƙananan injinan stepper suna fuskantar ƙalubale kamar su resonance, vibration, da kuma yiwuwar asarar matakai. Domin tabbatar da cewa suna aiki ba tare da wata matsala ba a cikin adaftar gwajin allurar lantarki, masana'antar ta ɗauki waɗannan dabarun ingantawa:

Cikakken amfani da fasahar tuƙin micro-stepping:Ta hanyar ƙananan matakai, ba wai kawai an inganta ƙudurin ba, har ma mafi mahimmanci, motsin motar yana daidaita, wanda ke rage girgiza da hayaniya sosai yayin rarrafe mai ƙarancin gudu, yana sa hulɗar na'urar ta fi dacewa.

Gabatar da tsarin kula da madauki mai rufewa:A wasu aikace-aikacen da ake yawan buƙata, ana ƙara na'urori masu ɓoye bayanai a cikin injinan stepper na micro don samar da tsarin sarrafa madauki mai rufewa. Tsarin yana sa ido kan ainihin matsayin motar a ainihin lokacin, kuma da zarar an gano rashin aiki (saboda yawan juriya ko wasu dalilai), zai gyara shi nan take, yana haɗa amincin ikon sarrafa madauki mai buɗewa tare da garantin aminci na tsarin rufewa mai rufewa.

一.Kammalawa

A taƙaice, aikin ƙananan injinan stepper a cikin adaftar gwajin allurar lantarki yana aiki a matsayin cikakken misali na canza umarnin dijital zuwa ƙungiyoyi masu daidaito a duniyar zahiri. Ta hanyar yin jerin ayyuka masu daidaito, gami da karɓar bugun jini, yin motsi na ƙananan matakai, da kuma kiyaye matsayi, yana ɗaukar muhimman ayyuka na daidaito daidai, matsi mai sarrafawa, da kuma duba mai rikitarwa. Ba wai kawai babban kayan aiki ne don cimma nasarar gwaji ta atomatik ba, har ma da injina na tsakiya don haɓaka daidaiton gwaji, aminci, da inganci. Yayin da kayan lantarki ke ci gaba da haɓaka zuwa ga ƙarancin yawa da yawan aiki, fasahar ƙananan injinan stepper, musamman fasahar micro-stepping da rufe-loop, za ta ci gaba da haɓaka fasahar gwajin lantarki zuwa sabon matsayi.

Lokacin Saƙo: Nuwamba-26-2025