Motar stepper motar lantarki ce da ke juyar da makamashin lantarki zuwa makamashin injina, kuma za a iya sarrafa karfin fitarwa da saurinsa daidai ta hanyar sarrafa wutar lantarki.

I, amfanin stepper motor

Babban daidaito

Matsakaicin jujjuyawar motsi na stepper yana daidai da adadin abubuwan shigarwa, don haka yana yiwuwa a daidaita daidaitattun adadin da yawan bugun jini don cimma daidaitaccen iko na matsayi na motar da sauri. Wannan halayyar ta sa injinan stepper ya yi fice a aikace-aikacen da ke buƙatar madaidaicin matsayi, kamar kayan aikin injin CNC, injin bugu, da injin ɗin yadi.

Motocin Stepper yawanci suna da daidaito tsakanin 3% zuwa 5% a kowane mataki kuma ba sa tara kuskure daga mataki na baya zuwa na gaba, watau ba sa haifar da kurakurai masu tarawa. Wannan yana nufin cewa stepper Motors iya kiyaye high matsayi daidaito da kuma motsi repeatability a kan dogon lokaci ko ci gaba da motsi.

Mai iya sarrafawa sosai

Ana samun aikin motar Stepper ta hanyar sarrafa bugun bugun jini, don haka ana iya tabbatar da sarrafa injin ta hanyar shirye-shiryen software. Wannan shirye-shiryen yana ba da damar injinan stepper don biyan buƙatun aikace-aikace iri-iri, kamar layin samarwa na atomatik, robotics, da sauran fannoni.

Tun da amsawar motar stepper kawai aka ƙaddara ta hanyar shigar da bugun jini, ana iya amfani da kulawar madauki mai buɗewa, wanda ya sa tsarin tsarin motar ya fi sauƙi kuma maras tsada don sarrafawa. Kula da madauki kuma yana rage rikitar tsarin da farashin kulawa.

Babban karfin juyi a ƙananan gudu

Motocin Stepper suna da babban ƙarfin juzu'i a ƙananan gudu, wanda ya sa su zama masu kyau a aikace-aikacen da ke buƙatar ƙananan gudu da babban ƙarfin wuta, irin su na'ura mai lakabin atomatik da na'urorin tattara kaya.

Motocin Stepper suna da matsakaicin karfin juyi lokacin da aka tsaya, fasalin da ke ba su fa'ida a aikace-aikace inda ake buƙatar kwanciyar hankali ko juriya ga lodi na waje.

Babban abin dogaro

Motocin Stepper ba su da goge-goge, don haka rage rashin aiki da hayaniya saboda goga. Wannan yana sa injinan stepper ya zama abin dogaro sosai, tare da rayuwar motar ta dogara da rayuwar bearings.

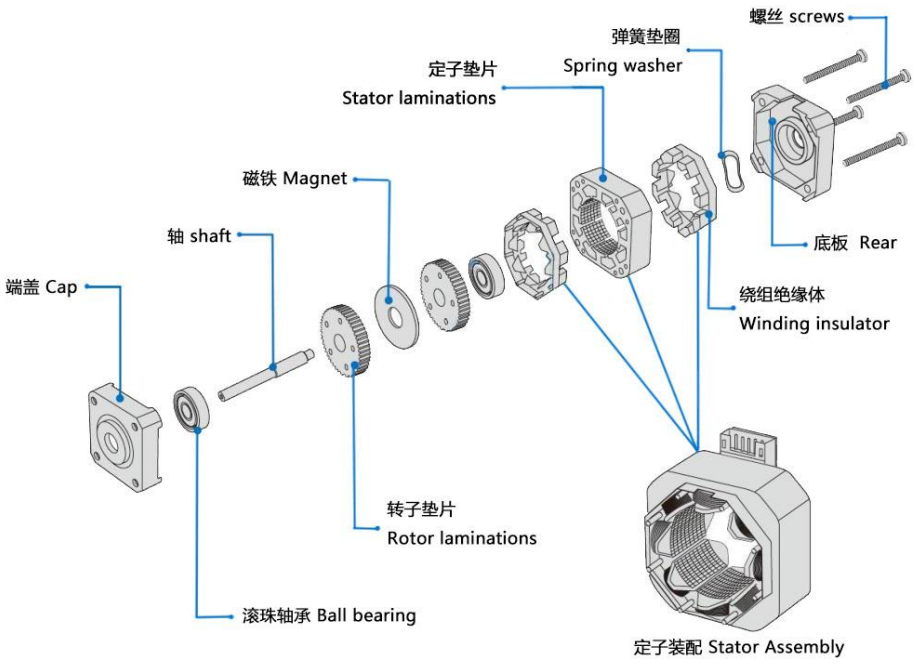

Motocin Stepper suna da tsari mai sauƙi, wanda ya ƙunshi sassa uku: motar kanta, direba da mai sarrafawa, yin shigarwa da kiyayewa cikin sauƙi.

Faɗin saurin gudu

Motocin Stepper suna da saurin saurin sauri, kuma ana iya canza saurin motar ta hanyar daidaita mitar bugun bugun jini. Wannan yana ba da motar stepper damar daidaitawa da saurin aiki daban-daban da buƙatun kaya.

Kyakkyawan Fara-Tsaya da Amsa Baya

Motocin Stepper suna amsawa da sauri don sarrafa sigina lokacin farawa da tsayawa, da kiyaye daidaito da kwanciyar hankali lokacin juyawa. Wannan fasalin yana sa motar motsa jiki a cikin buƙatar farawa-tsayawa akai-akai da juyawa na aikace-aikacen yana da fa'ida.

II, rashin amfanin stepper Motors

Sauƙi don rasa mataki ko wuce gona da iri

Idan ba a sarrafa shi da kyau ba, injinan stepper suna da saukin kamuwa zuwa mataki ko wuce gona da iri. Bayan mataki yana nufin cewa motar ta kasa jujjuyawa daidai da ƙayyadaddun adadin matakai, yayin da ba ta mataki na nufin cewa motar tana jujjuya fiye da ƙayyadaddun adadin matakai. Duk waɗannan abubuwan biyu suna haifar da asarar daidaiton matsayi na motar kuma suna shafar aikin tsarin.

Ƙirƙirar fita daga mataki da wuce gona da iri yana da alaƙa da abubuwa kamar nauyin motar, saurin juyawa, da mita da girman siginar sarrafawa. Don haka, lokacin amfani da injin motsa jiki, waɗannan abubuwan suna buƙatar yin la’akari da su a hankali da kuma ɗaukar matakan da suka dace don guje wa faruwar fita daga mataki da wuce gona da iri.

Wahalar kai manyan saurin juyawa

Gudun jujjuyawar injin stepper yana iyakance ne ta hanyar ƙa'idarsa ta aiki, kuma yawanci yana da wahala a cimma babban saurin juyi. Ko da yake yana yiwuwa a ƙara saurin motar ta hanyar ƙara yawan siginar sarrafawa, yawan mita zai haifar da matsaloli kamar dumama mota, ƙara yawan hayaniya kuma yana iya lalata motar.

Sabili da haka, lokacin amfani da injin motsa jiki, ya zama dole don zaɓar kewayon saurin da ya dace bisa ga buƙatun aikace-aikacen kuma guje wa gudu cikin sauri na dogon lokaci.

Mai hankali don ɗaukar canje-canje

Motoci masu tafiya suna buƙatar sarrafa ainihin lokaci na lamba da mitar bugun jini na yanzu yayin aiki don tabbatar da madaidaicin iko da matsayi da sauri. Duk da haka, a cikin yanayin manyan canje-canjen kaya, bugun jini mai sarrafawa na yanzu zai damu, wanda zai haifar da motsi mara kyau har ma da matakan da ba a sarrafa ba.

Don magance wannan matsala, za a iya amfani da tsarin kula da tsarin rufewa don saka idanu da matsayi da sauri na motar da daidaita siginar sarrafawa bisa ga ainihin halin da ake ciki. Duk da haka, wannan zai ƙara rikitarwa da tsadar tsarin.

Ƙananan inganci

Tunda ana sarrafa injinan stepper tsakanin tsayawa da farawa akai-akai, ingancin su ya yi ƙasa kaɗan idan aka kwatanta da sauran nau'ikan injina (misali DC Motors, AC Motors, da sauransu). Wannan yana nufin cewa stepper Motors cinye mafi iko ga guda fitarwa ikon.

Domin inganta ingantattun ingantattun injinan stepper, ana iya amfani da matakan kamar haɓaka algorithms na sarrafawa da rage asarar mota. Koyaya, aiwatar da waɗannan matakan yana buƙatar takamaiman matakin fasaha da saka hannun jari.

III, iyakokin aikace-aikacen injinan stepper:

Motocin Stepper ana amfani da su sosai a fagage da yawa saboda fa'idodinsu na musamman da wasu iyakoki. Mai zuwa shine cikakken bayani game da iyakokin aikace-aikacen injinan stepper:

Robotics da tsarin sarrafa kansa

Motocin Stepper ana amfani da su sosai a cikin robobin masana'antu, layukan samarwa na atomatik, da sauran fannoni. Suna iya sarrafa saurin motsi da alkiblar mutummutumi da kuma gane madaidaicin matsayi da amsa cikin sauri a cikin ayyukan samarwa na atomatik.

CNC Machine Tools

Masu bugawa

Ana amfani da injinan Stepper don sarrafa motsin shugaban buga a cikin na'urori kamar tawada da firintocin laser. Ta hanyar sarrafa motsin motar daidai, ana iya gane rubutu mai inganci da bugu na hoto. Wannan fasalin yana sanya injinan stepper ana amfani da su sosai a cikin kayan bugawa.

Na'urorin likitanci

Ana amfani da injinan Stepper a kayan aikin hoto na likita (misali na'urorin X-ray, CT scanners, da sauransu) don fitar da motsin firam ɗin dubawa. Ta hanyar sarrafa motsin motar daidai, za a iya gane hoton mai haƙuri cikin sauri da daidai. Wannan fasalin yana sa injinan stepper ke taka muhimmiyar rawa a cikin kayan aikin likita.

Jirgin sama

Ana amfani da injinan Stepper don sarrafa motsi na masu kunnawa a cikin kayan aikin sararin samaniya kamar sarrafa halayen tauraron dan adam da tsarin motsa roka. Motocin Stepper suna nuna kyakkyawan aiki a ƙarƙashin buƙatun babban daidaito da kwanciyar hankali. Wannan sifa ta sa injinan stepper ya zama muhimmin sashi na filin sararin samaniya.

Kayayyakin Nishaɗi da Wasanni

Ana amfani da injinan Stepper don sarrafa motsi na masu kunnawa a cikin na'urori irin su na'urar zane-zanen laser, firintocin 3D, da masu sarrafa wasa. A cikin waɗannan na'urori, daidaitaccen iko na injin motsa jiki yana da mahimmanci don samun samfur mai inganci da ƙwarewar mai amfani.

Ilimi da Bincike

Ana amfani da injinan Stepper don sarrafa motsi na dandamali na gwaji a cikin yanayi kamar kayan aikin dakin gwaje-gwaje da kayan koyarwa. A cikin ilimi, ƙarancin farashi da babban daidaito na injinan stepper ya sa su zama kayan aikin koyarwa masu kyau. Ta hanyar amfani da madaidaicin halayen sarrafawa na injinan stepper, za su iya taimaka wa ɗalibai su fahimci ilimin kimiyyar lissafi da ƙa'idodin injiniya.

A taƙaice dai, injinan stepper suna da fa'idar daidaitattun daidaito, ƙarfin sarrafawa, ƙarancin gudu da ƙarfin ƙarfi mai ƙarfi, da babban abin dogaro, amma kuma suna da lahani na kasancewa cikin sauƙi daga mataki ko daga mataki, da wahalar cimma saurin jujjuyawa mai girma, mai kula da sauye-sauyen kaya, da ƙarancin inganci. Lokacin zabar stepper Motors, wajibi ne a yi la'akari da fa'idodi da rashin amfaninsu da kuma iyakokin aikace-aikacen bisa ga buƙatun aikace-aikacen don tabbatar da aiki da kwanciyar hankali na tsarin.

Lokacin aikawa: Nuwamba-14-2024